About Us

Who We Are

A.P. Rubber Industries established in 2004 and is one of the largest manufacturer of wide range of rubber and silicon products. Our manufacturing plant is a perfect example of sophisticated technology and a skilled workforce working hand in hand. The most modern machinery imported from Japan gives us the technological edge required to maintain its current consistency and excellence. Our plant is well equipped with the best infrastructural back up. A highly qualified and well –trained work force further adds to the efficiency and productivity of the plant. The plant is a benchmark in excellence, the result of complete synchronization between men and machines. Ever setting standards to create new traditions in quality and value.

- Cost Effective

- Timely Delivery

- Quality Products

- Customer Satisfaction

wHY US ?

We provide our customers with leading edge technology. With over 17 years in business, we’ve established a reputation for excellence and regularly source crumb rubber to the largest contractors and synthetic turf product companies across India and outside.

Most importantly, we focus, not on orders, but on lasting partnerships with quality-minded customers, and we guarantee satisfaction by treating each customer like our only customer.

TRUSTED BY LEADING BRANDS

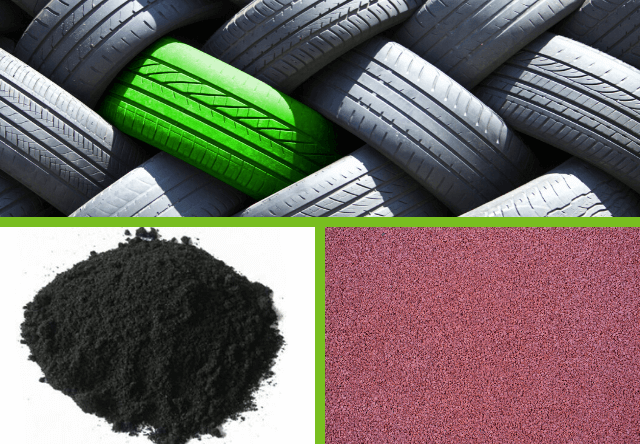

MANUFACTURING PROCESS

We use the ambient mechanical grinding method. In this process, the breaking up of a scrap tire happens at or above normal room temperature. Ambient grinding is a multi-step technology and uses whole or pre-treated car or truck tyres in the form of shred or chips, or sidewalls or treads. The rubbers, metals and textiles are sequentially separated out. Tyres are passed through a shredder, which breaks the tires into chips.

The chips are fed into a granulator that breaks them into small pieces while removing steel and fiber in the process. Any remaining steel is removed magnetically and fiber through a combination of shaking screens and wind sifters. Finer rubber particles can be obtained through further grinding in secondary granulators and high-speed rotary mills.

Ambient grinding is the production process used by the majority of crumb producers. Our varied manufacturing capabilities help keep costs low and decrease the lead times of your rubber parts.